Concrete technology, as we know it today, began in England with the industrial production of cement. The Englishman Hyatt was the first to recognize that concrete and steel have practically the same coefficient of expansion and with the right combination and placement, concrete exerts compressive forces and iron the tensile forces. Concrete today, exists in a wide variety and depending on its composition meets the different static and construction requirements. Without losses it is poured into prepared molds of any shape and is the standard of modern building materials. Concrete, especially reinforced concrete, is a suitable material for load-bearing building elements, for frames, walls, slabs, flat structures, frames, etc.

The qualities of concrete are distinguished in relation to the density of its composition:

- Normal concrete (2t/m3 to 2.8t/m3) consists of sand and gravel (gravel). For this category we use the word “concrete”.

- High strength concrete (over 2.8t/m3), which also contains magnesite or iron flour and is used in the construction of reactors.

The compressive strength of concrete, depending on the amount of cement content, starts from 5.0 N / mm2 and reaches over 60N / mm2.

The static and physical properties of concrete, specifically in masonry, are the following:

- Bearing capacity, compressive strength: the high strength of concrete allows us to build walls with relative thickness such as e.g. 15cm instead of 24cm. common wall with substantial gains on a useful area of the premises.

- Thermal insulation properties: the thermal absorption of concrete is, due to its high weight, very good.

- Sound insulation properties: the concrete with its density and high specific weight, has good insulation for airborne sounds and very good for body sounds.

The structure of frame structures is the same for all types of materials. The function of the load-bearing walls is replaced by columns that support the main beams. Columns and beams form the frame. Their connection points are the knots, which can be articulated or rigid. The moving loads are transferred from the slabs and beams together with their same weights to the heads of the columns of each floor, and from there to their bases and the immediately lower floor. Eventually they end up in the foundations and the foundation ground. The same loads of filling walls, etc. parallel or perpendicular to the main beams, are taken by secondary beams and transferred through the slabs to the main beams.

Thus, in a building made of reinforced concrete in terms of mechanical properties, concrete undergoes compressive strain and steel undergoes tensile strain, which determines the position of the reinforcement in the carriers.

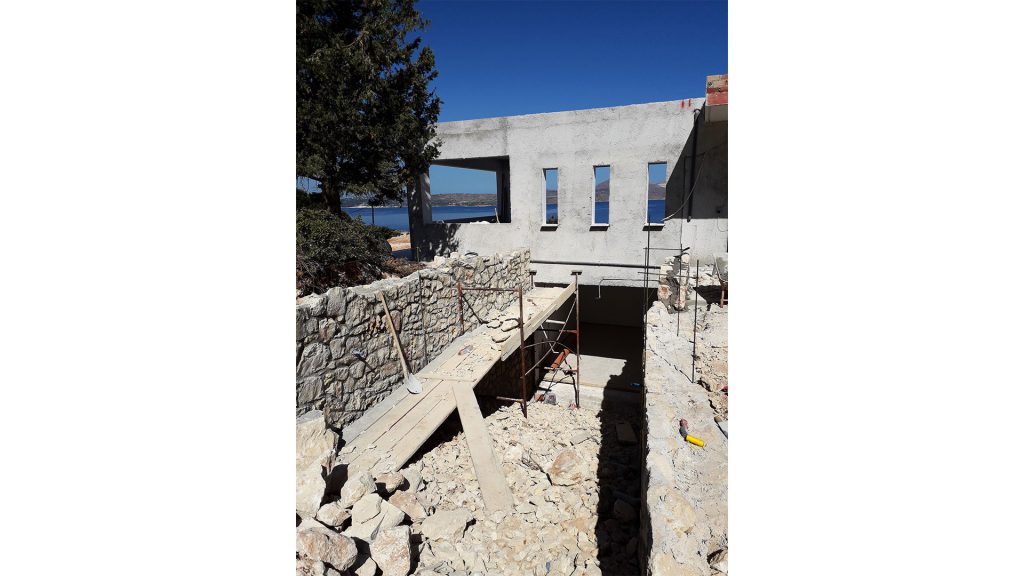

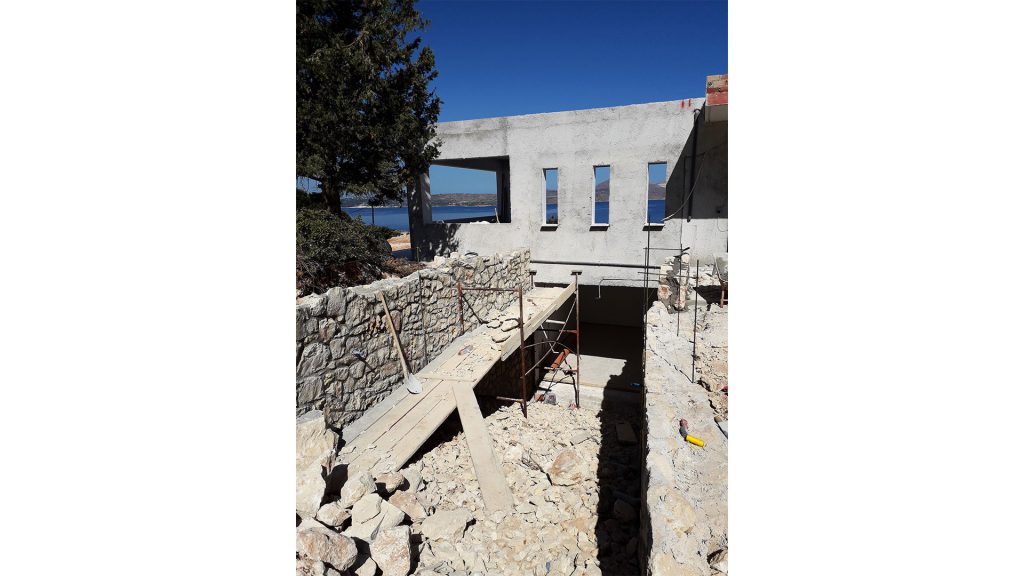

The main frame of the building is made of reinforced concrete. The concrete is mixed according to the specifications of the seismic study of the building. The main factors that affect the seismicity of the building are: the seismicity of the area where the construction takes place, the type of building and the quality of the existing soil. The frame of the building is made of reinforced concrete C20/25 or C25/30 and quality steel B500C. The floors of the buildings are made of reinforced concrete of matching category and are reinforced with structural grids T131 or T191. The steel reinforcement of the building will be constructed according to the Structural Plans of the Civil Engineer. During the construction process with concrete, chemical admixtures (liquefiers) and vibrators are used for better workability and compaction of the concrete. Particular attention is paid to the compaction of the concrete on all surfaces, as well as to its anchoring according to the seismic regulations.

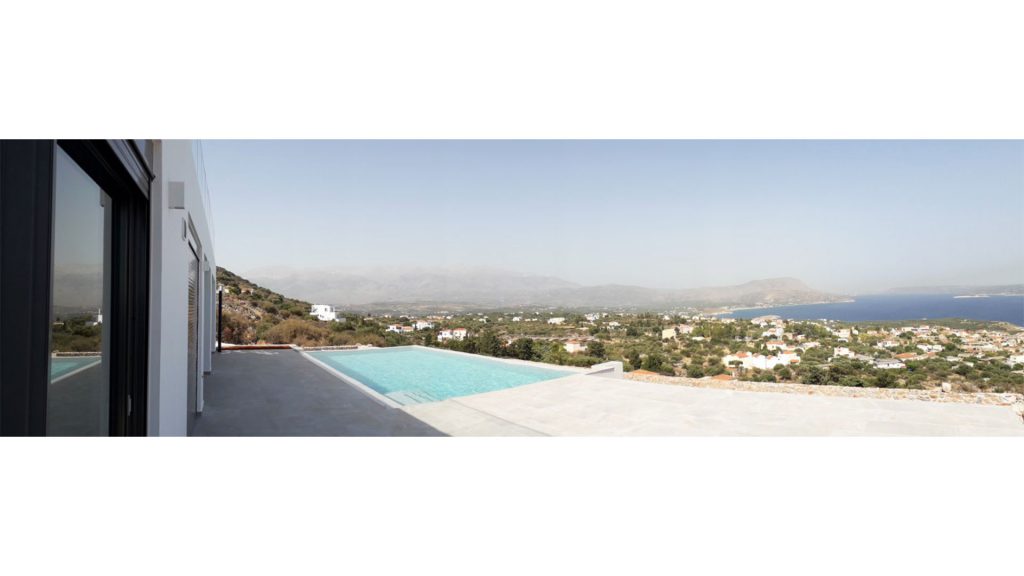

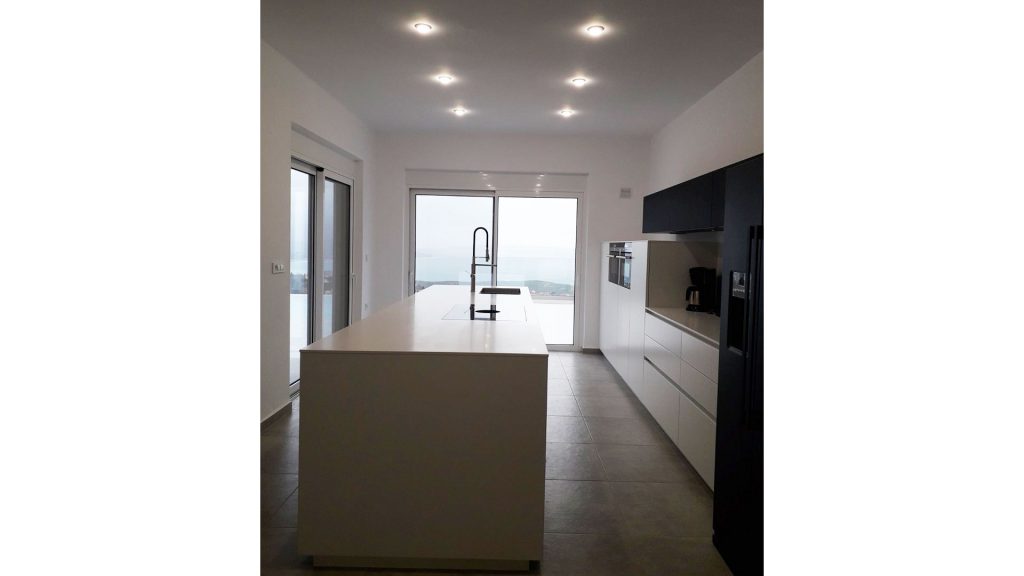

Concrete (reinforced concrete) construction is based on the required specifications as well as the static designs issued in the building permit. With the completion of planning and building inspections, construction continues on stages that have been agreed with the client. The time of completion of the construction depends on the size of its size. Our responsibility is to deliver the project to the client “with turn-key”.

facebook.com/benakisconstructions

facebook.com/benakisconstructions  instagram.com/benakisconstructions

instagram.com/benakisconstructions  youtube.com/benakisconstructions

youtube.com/benakisconstructions